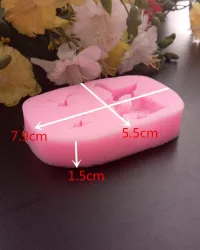

Silicone Moulds used with Epoxy Resin

Mix your resin and pour it into the mould. Prior to pouring the resin you can add suitable pigments and colourants. You can use multiple resin layers if required. Carefully use a torch to pop any bubbles if required but take care not to damage the mould. Keep the mould on a flat surface in a protected area that is free from insects and dust while the resin cures. Only remove the resin casting from the mould once it has cured.

It is easy to drill a hole through the cured resin, after it has been removed from the mould, for use in jewellery.

Resin casting made in the pink moulds may tend to have a low gloss finish. There are various ways you can finish off the removed castings to create a high gloss:

- You can “paint on” a thin layer of the same resin you cast with.

- You can apply a number of stages of sanding and polishing. You can see many examples of the sanding and polishing of resin on YouTube.

***Colour of mould may change without prior notice***

Reviews

There are no reviews yet.