Applications

- Foundry patterns, core boxes, negatives, pattern plates

- Checking casts and jigs

- Detailed models, prototypes and props

- Vacuum forming moulds using the product filled with aluminium powder in order to increase thermal conductivity

Properties

- Fast cure and fast demold

- Very good temperature resistance

- Fully cured castings are tough, high strength, machinable and paintable

- Easy to colour with a variety of pigments and powder fillers.

- Resist moisture and mild solvents

Processing

- The processing and material temperature should be between 20-25 °C.

- Immediately replacing the lids on both containers after dispensing product will help prolong the shelf life of the unused product.

- Mixing tools and containers should be clean and made of metal, glass or plastic.

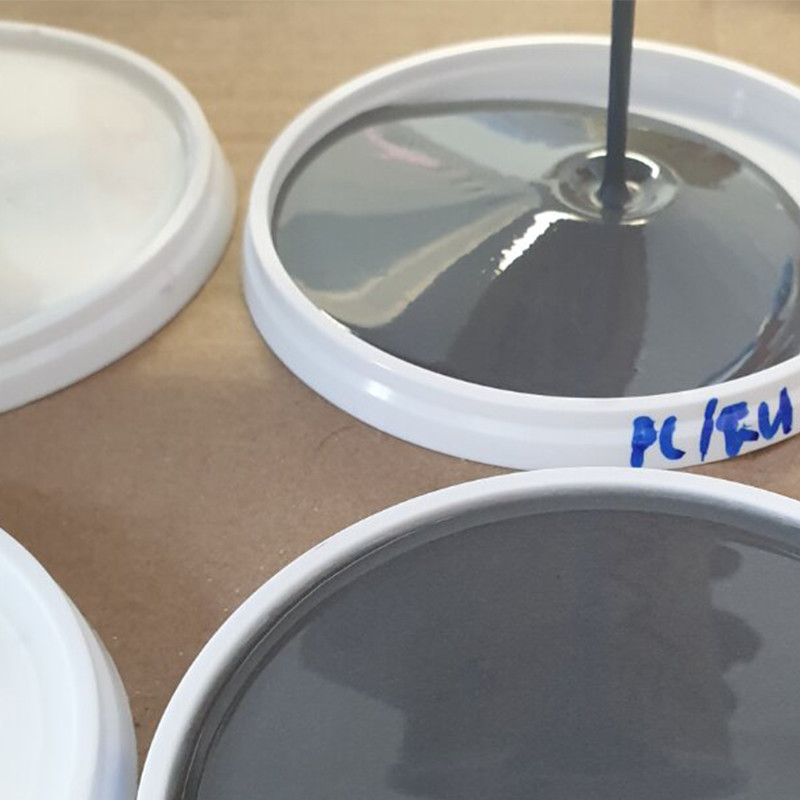

- The A component must be stirred well before use as some fillers might be prone to sedimentation.

- The fillers should first be mixed equally into the individual A and B components. This allows for better mixing of the two components.

- Mixing should be done in a well-ventilated area.

- Wear safety glasses, long sleeves and rubber gloves to minimise contamination risk.

Health & Safety

Skin contact must be avoided by wearing protective gloves. Overalls or other protective clothing should be worn when mixing, laminating or sanding. Contaminated work clothes should be thoroughly cleaned before re-use. Eye protection should be worn if there is a risk of liquid product entering the eyes. Use this product with at least room size ventilation or in proximity to a forced outlet air vent and do not inhale/breath fumes. Fumes will quickly dissipate with adequate ventilation. Respiratory protection should be worn if there is insufficient ventilation.

Transport & Storage

These products have a limited shelf life and the shelf life is reduced after opening. Remaining product should be used as soon as possible. Immediately replacing the lids on both containers after dispensing product will help prolong the shelf life of the unused product. All liquid urethanes are moisture sensitive and will absorb atmospheric moisture which results in foaming. Any accidental spillage should be soaked up with absorbent material (sand, sawdust etc.) Storage should be in a warm dry place out of direct sunlight.

Reviews

There are no reviews yet