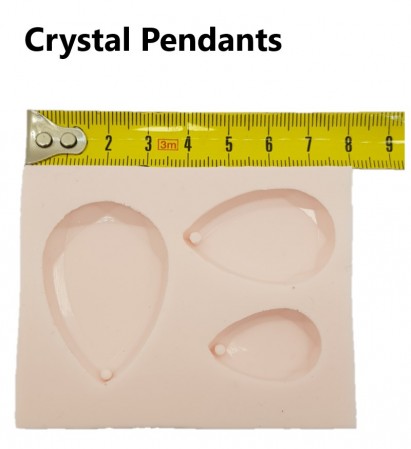

Silicone Mould – Crystal Pendant

This silicone mould can be used for casting with various materials such as Casting Resins, Polymer Clays, and Plaster of Paris.

👉 When using Casting Resins, first ensure you mix the resin thoroughly to eliminate as many air bubbles as possible. Then, pour the resin slowly and steadily, allowing it to reach every corner of the mould. To help release any trapped air, gently tap the mould on a flat surface. Additionally, for best results, consider using a handheld blow torch to remove any remaining surface bubbles.

✨ To enhance your creations, you may incorporate elements such as Resin Pigments, Mica Glitters, or inclusions like dried flowers and Metallic Foil Flakes. These additions can bring vibrant colour and unique textures to your final pieces.

➡️ For Polymer Clays like Das or FIMO, begin by conditioning the clay—knead it until it becomes soft and pliable. Then, carefully press it into the mould, ensuring it fills all areas evenly while avoiding any air pockets.

✅ Once the material has fully cured or baked, gently flex the mould to release the finished piece. Doing so helps avoid any cracks or distortions.

🪄 To achieve a refined finish, sand or polish the piece as needed. This extra step can greatly enhance the overall look and feel of your jewellery.

🧼 For mould maintenance, wash them using warm water and mild soap. Regular cleaning helps maintain the moulds’ integrity and ensures quality results with each use.

🎨 Overall, silicone moulds offer jewellery makers a convenient way to craft customised pieces, sparking endless creative possibilities.

📦 Finally, store the moulds properly—preferably in a cool, flat space—to protect them and extend their lifespan.

Reviews

There are no reviews yet